Mounting plates for pre-press or post-press has never been so easy

CORRUGATED PLATE MOUNTER

Site map:

Flexo products > Plate mounters > Plate mounter for CORRUGATED

CORRUGATED

THE PLATE MOUNTER FOR FLEXO PRINT ON CORRUGATED CARTON BOARDS

WELCOME TO THE 4.0 DIGITAL CORRUGATED MOUNTER

DIGITAL CONTROL FOR PRECISE AND REPEATABLE MOUNTINGS

Overview

A big innovation from SYS TEC

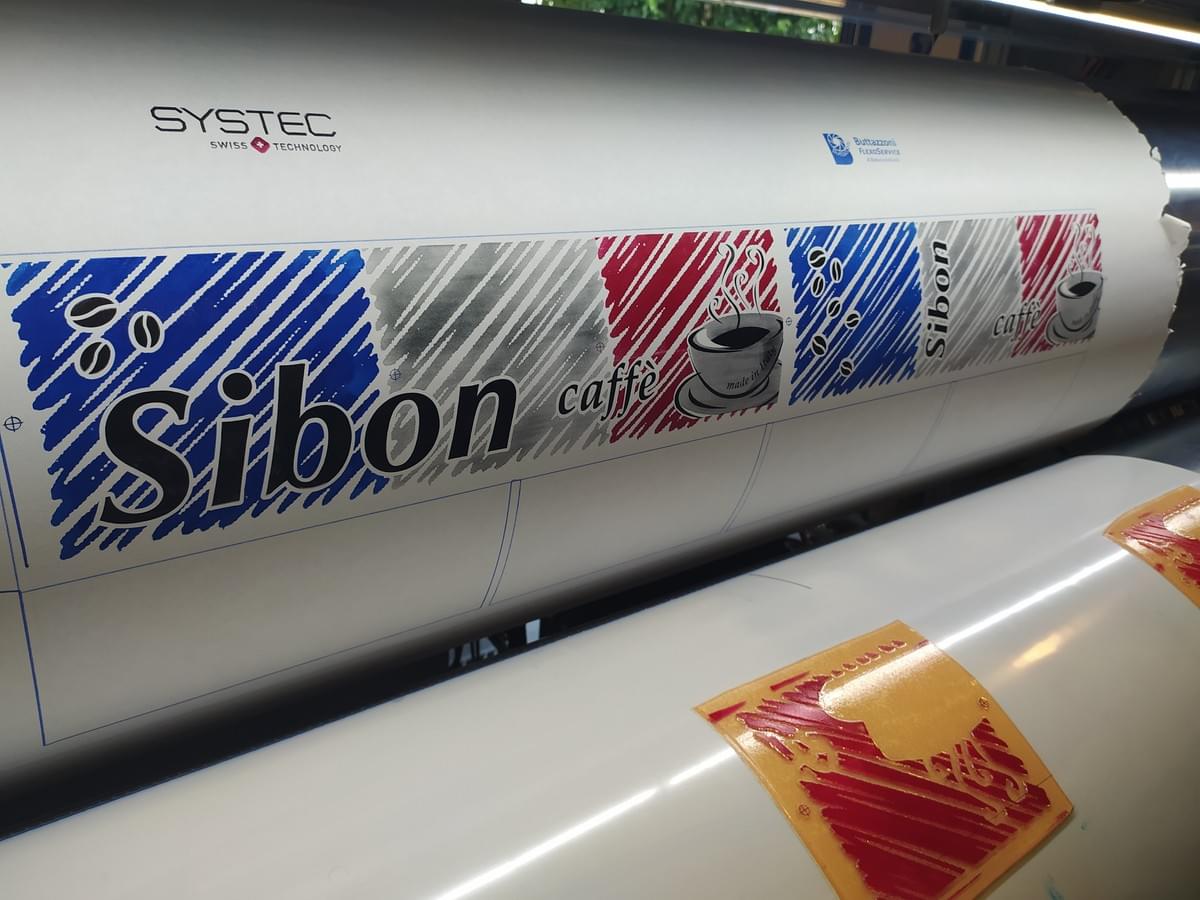

CORRUGATED is an innovative machine developed for plate mounting in the carton board industry.

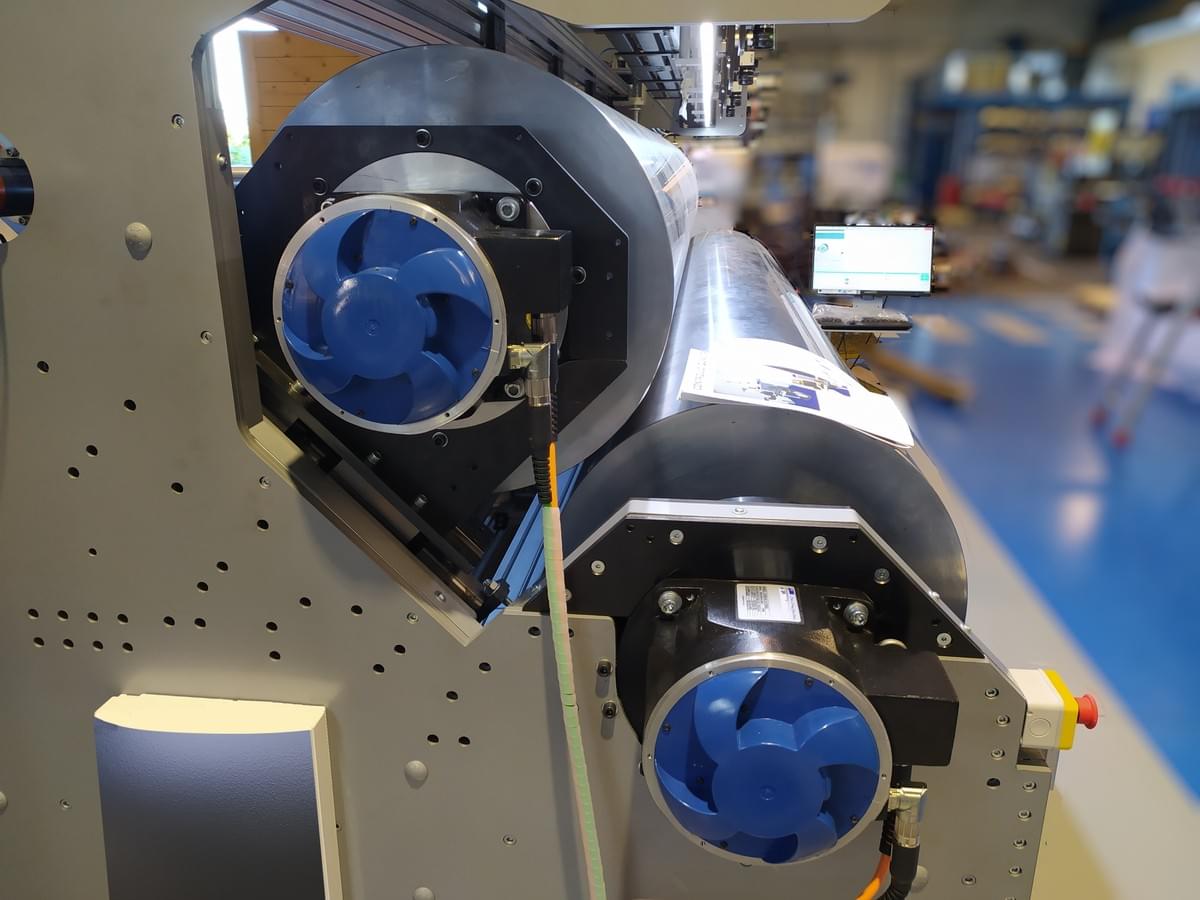

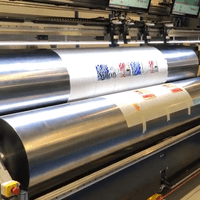

It is a fully electronic system, equipped with 2 drums dedicated to the mounting and proofing:

- the proofing drum is designed for dry proof on paper, and it can be equipped with the plotter pen for drawing the boxes die-cuts

- the main drum is designed to mount the mylar/polyester sheets for the plate, supporting the Matthews/Bobst clamping systems (T or J clamps) or slots

The machine is equipped with 3 touch screen monitors: the 2 big sliding monitors are in front of the operator, in the upper side of the machine, and 1 monitor is installed on a sliding console in the side.

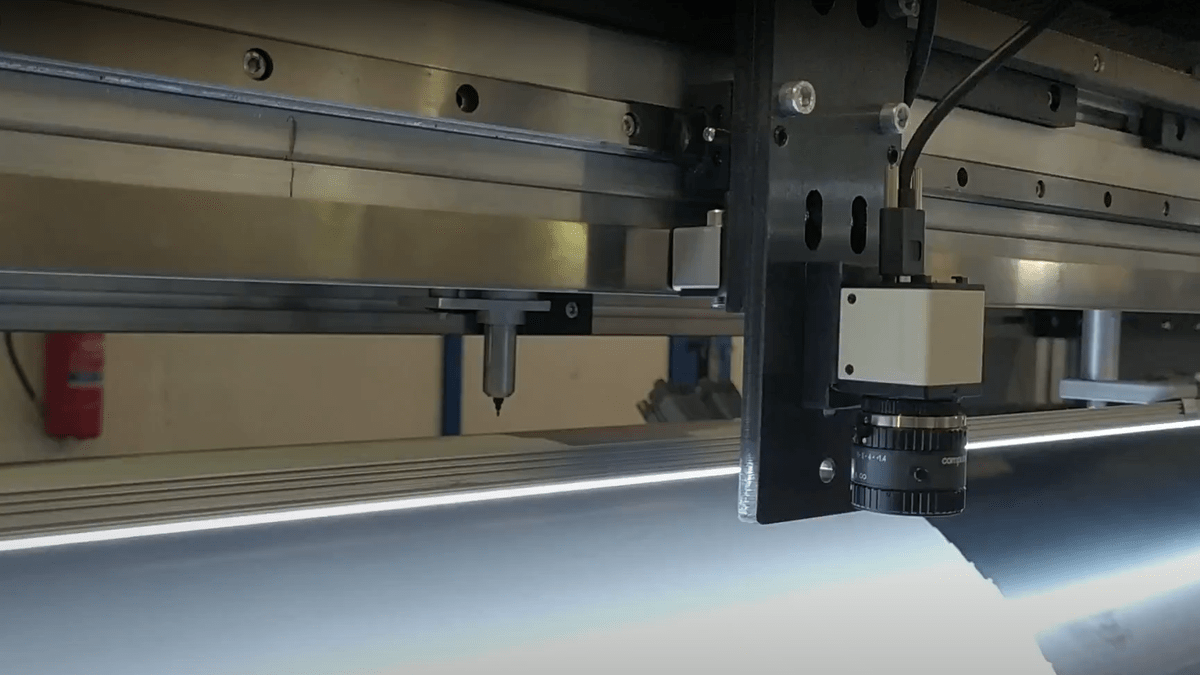

Cameras

The system is equipped with 4 motorized HD digital cameas

The machine is equipped with 4 HD digital cameras 100x zoom, motorized by means of electrical motors sliding on a linear rack, with linear encoders for reading the real-time position of the cameras without connection of mechanical parts (no ball screws).

The TOUCHLESS SLIDING SYSTEM for the cameras tracks the position of the operator and follow him without touching them

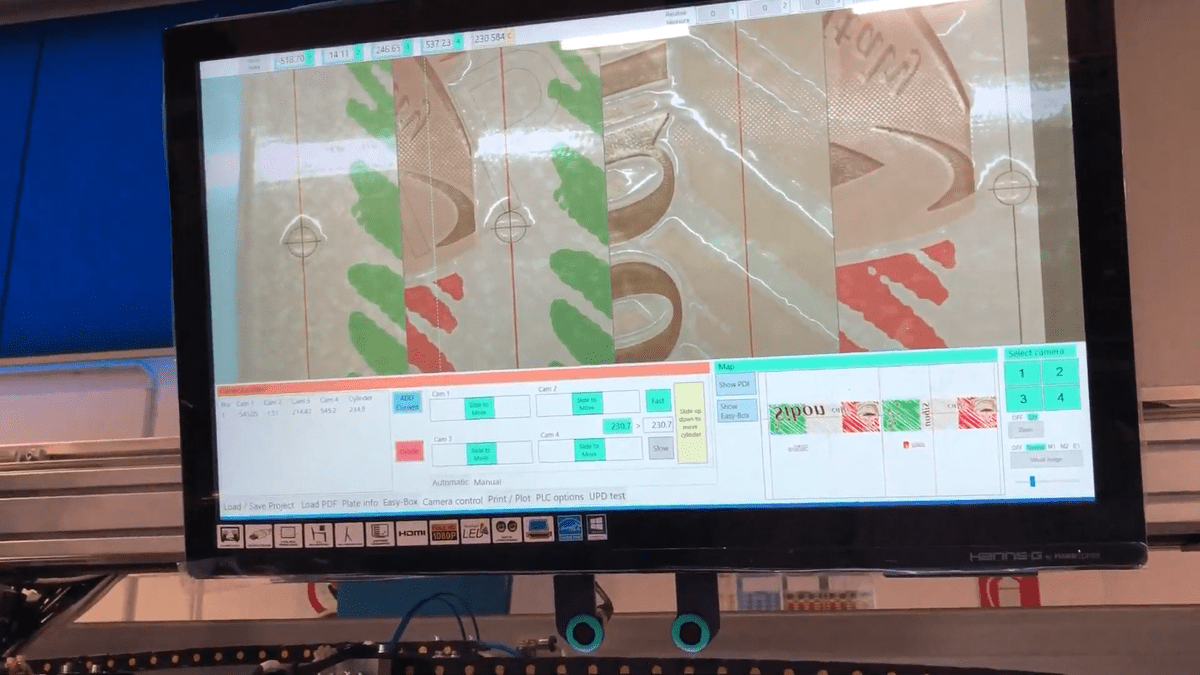

Software

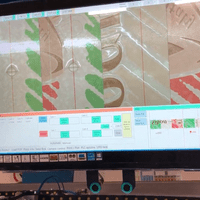

A revolutionary PDF-based software

CORRUGATED is managed by an amazing HMI (human-machine interface) developed by our company for Windows 10.

The jobs are based on the PDF repro-file, which is the comprehensive layout for the positioning of the plates.

The PDF is overlaid to the screen and the operator can easily position the plate in matching the theoretical positions of the elements on the plate.

A fantastic "drag & drop" function of the cameras on the PDF, allows to position the cameras and the drum, easily and precisily.

Gearless motors

An advanced electronics with powerful gearless motors

The rotation of the drums is provided by direct torque motors with electronic servo-drives.

This system automatically adjusts the speed of the drums to recover the plate elongation, to obtain a 1:1 ratio proof print.

ADVANTAGES:

- It works with any kind of cross-marks or pattern on plates

- Easy user interface, touch screen operated

- PDF file overlay

- High mounting precision

- Automatic recovery of the plate elongation

- Reduction of the time needed to mount the plates

- Elimination of the human error while mounting the plates

- Jobs repeatability

- The most advanced technology available on the market.

Highlights about CORRUGATED

We let the technology speaks for itself.

CORRUGATED PLATE MOUNTER

AVAILABLE FOR:

- PRE-PRINT

- POST-PRINT

- CYLINDERS OR SLEEVES

Equipped with Matthews/Bobst locking system (T clamps, J clamps) or slots for the mylar plastic sheet.TECHNOLOGY:

- Automatic drawing of the carton box shape on the drum

- Easy User-friendly interface with Wizard Options, based on Microsoft Windows 10

- N. 4 motorized cameras, equipped with linear encoders and touchless sliding system

- N. 3 touch screen monitors: 2 in the front of the machine, sliding on a rail with electric movement TOUCHLESS, and 1 on the sliding console

MOTORS AND ELECTRONICS:

- Fully electronics drums rotation with direct torque motors and servo-drives.

- N. 2 powerful gearless torque motors with high-resolution resolvers, for the most precise positioning of the drum

- Automatic digital recovering of the plate elongation

SOFTWARE:

- PHOTOSPLIT CORRUGATED VERSION, with touch screen HMI

- Ability to create unlimited jobs

- VIRTUAL IMAGE PDF: for the mounting of the plates using the PDF repro-file as the general layout of the job

- Ability to connect to the LAN network

- Remote support app (SYSTEC Service Center)

- Augmented reality support app

A closer look

Take a look and enjoy!

- Contact Us

Fill the form to ask more information or to receive the brochure

Contact Us

SYSTEC CONVERTING

Powered by

W-TEC Srl

Via Unione 2

22075 Lurate Caccivio (CO)

P.IVA / VAT IT04123480131