THE SEMI-AUTOMATIC PLATE MOUNTER FROM SYS TEC

STAR9

AUTOMATIC PLATE MOUNTER

Site map:

Plate mounters > Wide web flexo > STAR9

WELCOME TO THE 4.0 DIGITAL FLEXO MOUNTER

DIGITAL CONTROL FOR PRECISE AND REPEATABLE MOUNTINGS

iTABLE 2.0, THE AUTOMATIC MOUNTER

A great innovation from SYS TEC

i-Table is the new automatic mounting system available for SYSTEC plate mounting machines.

It arose from SYSTEC research & development and permits the automatic positioning of the plates in the right mounting position, with the finest precision (0.01mm)

ABOUT iTABLE 2.0

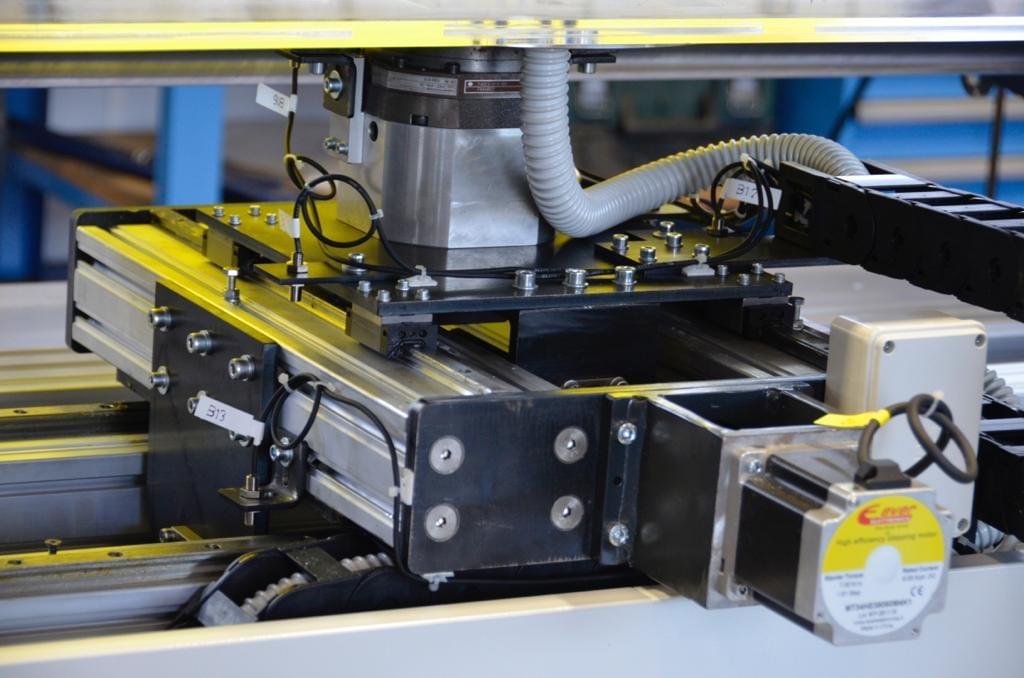

The smart heart of the automatic mounter

iTable 2.0 is an intelligent robotized table, it can move with 3 freedom degrees positioning the plates with the precision of microns.

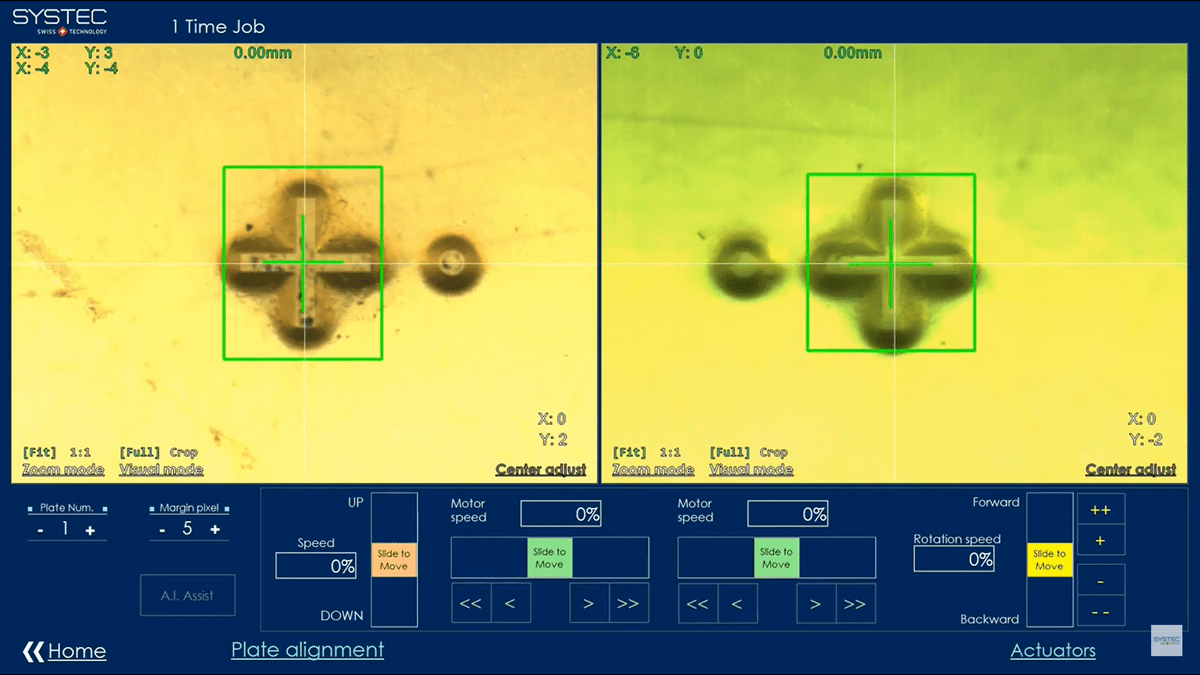

It works in combination with advanced digital cameras, recognizing the cross-marks on the plates and automatically comparing them with the reference Virtual Image, and then adjusting the plate position on the sleeve.

The system provides the automatic positioning of the plates on the sleeve and the sticking of the plates on the tape with the automatic pressing roll.

HOW DOES IT WORK?

Less than 5" to align a plate

The operator roughly places the plate on the table in the cameras' visioning area, then the machine automatically provides the following steps:

- Automatic recognition of the marks on the plate and comparing with the Virtual Image

- Automatic adjustment of the plate to the target position

- Automatic fixing of the plates on the adhesive tape with the pressing roller

ADVANTAGES:

A fast ROI

- It works with any kind of cross-marks or pattern on plates

- High mounting precision (mounting tolerance: 1 micron)

- Reduction of the time needed to mount the plates only 30 seconds to mount a plate!

- Elimination of the human error while mounting the plates

- Jobs repeatability

- The most advanced technology available on the market.

Focus on the STAR9

DESIGNED FOR MICRODOTS

The highest magnification

The new STAR9 is designed to mount the smallest microdots with the highest precision and repeatability.

The cameras work close to the plate, in order to have the highest magnification, and the mandrel position is adjusted up/down by the machine to match the correct working position.

With heavy-duty and reliable mechanics completely redesigned to easily handle dynamic torsions and heavy loads.

A precise system, designed to meet the highest quality standards.

A COMPLETE CONFIGURATION

Equipped with all the devices you need

STAR9 comes with a very complete configuration:

- Motorized cameras with TOUCHLESS system

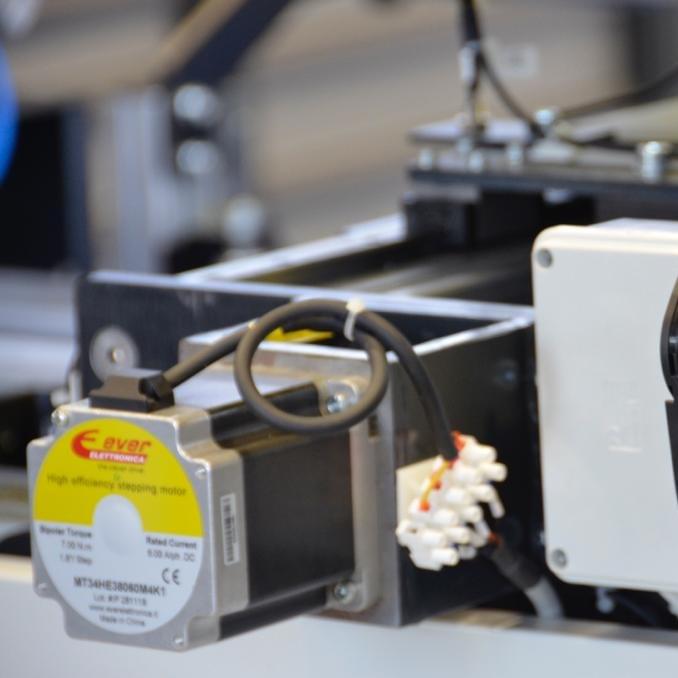

- Motorized mandrel with direct drive

- Touch screen monitor

- Double-sided table

- Pressure roller with notched engraved surface

- Sliding monitor with TOUCHLESS system

THE CORE IS THE SOFTWARE

We've developed the smartest solutions

The heart of the 4.0 automation is surely the software.

We develop in-house the smartest solutions and the STAR9 will surprise you for the easy interface and the fast workflow.

Our software will assist the operator during the mounting operation with a great wizard interface!

Technical highlights about STAR9

We let the technology speaks for itself.

FEATURES

- Structure for SLEEVES

- Machine designed to mount with microdots.

- The plate is laid on the double table and the position of the mandrel is adjusted up/down to match the external repeat in the mounting position.

CAMERAS

2 HD digital hi.res. digital cameras

with high optical magnification > 100x

Camera movement: MOTORIZED

with TOUCHLESS SLIDING SENSOR

Encoders on cameras for real-time positioning: YES

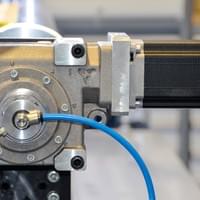

MANDREL ROTATION

MOTORIZED with direct stepper motor

ZERO BACKLASH GEARBOX

CONTROL OF THE ROTATION AND MANDREL ANGULAR POSITION

SOFTWARE

- PHOTOSPLIT ARTIFICIAL INTELLIGENCE INTERFACE

- VIRTUAL IMAGE with "MOUNTING ASSISTANT"

- SOFTWARE FOR AUTOMATIC STAGGERING POSITIONS

- REMOTE ASSISTANCE (Sys Tec Service Center app)

A closer look

Contact Us

Fill the form to ask more information or to receive the brochure

Contact Us

SYSTEC CONVERTING

Powered by

W-TEC Srl

Via Unione 2

22075 Lurate Caccivio (CO)

P.IVA / VAT IT04123480131