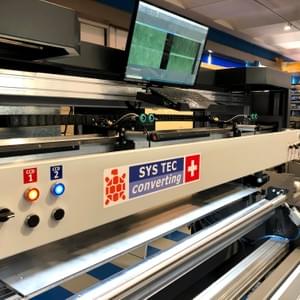

THE PLATE MOUNTERS

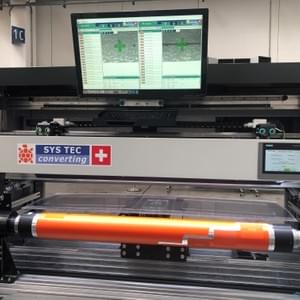

FOR WIDE WEB FLEXO

Discover our wide web flexo plate mounters!

A complete range of mounter for all the needs

STAR 3

Motorized

plate mounter

This is the entry model:

- motorized cameras and mandrel

- HD digital cameras

- MOUNTING ASSISTANT for pattern recognition

STAR 5

Electronic

plate mounter

Like the STAR3, but with more:

- electronic control of the axis with absolute encoders

- ability to save and load jobs,

STAR 7

Semi-automatic

plate mounter

Like the STAR5, but with more:

- automatic positioning of the mandrel according to the repeat

- automatic sticking of the plate

STAR 9

Automatic

plate mounter

Like the STAR7, but with more:

- automatic mounting of any plate, in any condition, with the iTABLE technology

- iTABLE smart mounting motorized table

STAR X

Full automatic

& robotic

Like the STAR9, but with more:

- automatic loading of the plates by gantry robit

- automatic search of the crosses on the plate

- this machine is fully automatic, go for a beer!

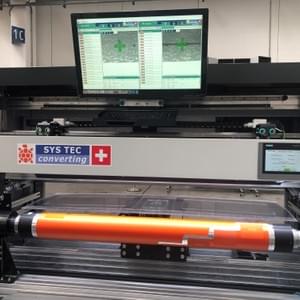

STAR 3

The motorized plate mounterWE'VE RAISED UP THE LEVEL OF THE BASIC PLATE MOUNTERS

FEATURES

- Structure for SLEEVES

- Machine designed to mount with microdots.

- The plate is laid on the double table and the position of the mandrel is adjusted up/down to match the external repeat in the mounting position.

CONFIGURATION

The new STAR 3 comes with a top-level configuration, with:

- Cantilever opening of the air mandrel, for an easy sleeves change-over

- 2 hi.res. HD digital cameras, suitable to mount even the smallest microdots

- Touch-screen monitor

- Motorized cameras on a linear rack

- Motorized mandrel rotation, with pedal command

- Double-sided mounting table

- Pressure roller for smooth sticking of the plate

- The new PHOTOSPLIT SOFTWARE for Windows 10, with the amazing function "MOUNTING ASSISTANT"

OPTIONS

Available as options:

- Pressure roller with "notched engraved surface"

- Double mounting table

- Sensor for automatic positioning of the mandrel in the height, according to the sleeve repeat

A SIMPLE MOUNTER WITH A HIGH-END TECHNOLOGY INSIDE

Have you ever seen such a complete mounter defined as "a basic" one?

The STAR 3 is designed for the customers who need to mount single plate jobs on the sleeve.The motors on the cameras and mandrel allow a very fast and flexible operativity, along with the HD cameras, which give the ability to mount even the smallest microdots.

The MOUNTING ASSISTANT software brings this machine into the Artificial Intelligence technology.

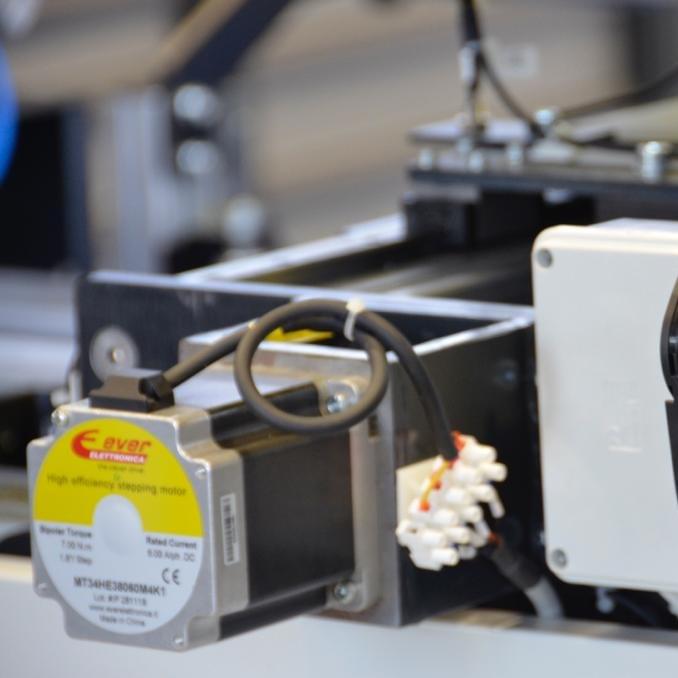

STAR 5

The electronic plate mounterFULLY CONTROLLED BY THE ELECTRONICS

HIGHEST PRECISION MOUNTINGS WITH ULTRA-HD DIGITAL CAMERAS AND AI

CONFIGURATION

- Cantilever opening of the air mandrel, for an easy sleeves change-over

- 2 hi.res. HD digital cameras, suitable to mount even the smallest microdots

- Touch-screen monitor

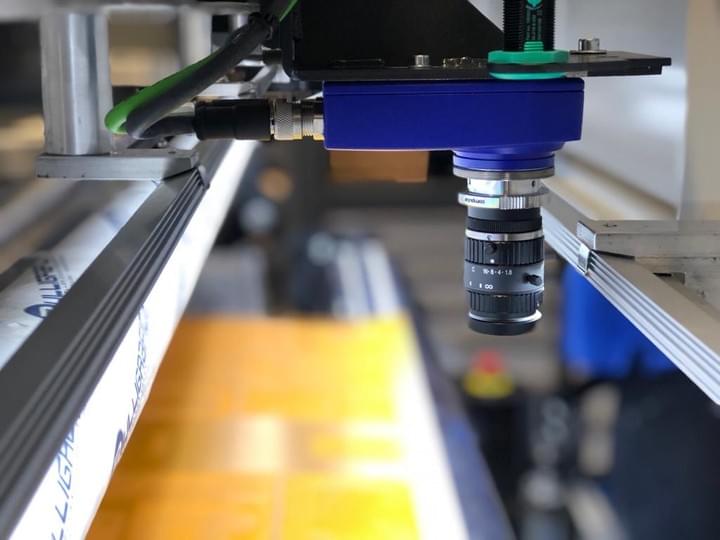

- Motorized cameras, with stepper motors and TOUCHLESS SLIDING system (patent pending): it is possible to move the cameras simply by putting a hand in front of them: the camera will follow it.

- Encoder for controlling the position of the cameras

- Motorized mandrel rotation, with the pedal command, with top-quality gearbox, perfect for STAGGERED MOUNTING

- Absolute rotative encoder for controlling the angle of the mandrel

- Single mounting table, in the back position

- The new PHOTOSPLIT SOFTWARE for Windows 10, with the amazing function "MOUNTING ASSISTANT"

OPTIONS

Available as options:

- Pressure roller with "notched engraved surface"

- Double mounting table

- Sensor for automatic positioning of the mandrel in the height, according to the sleeve repeat

- USB 3.0 digital cameras, with faster live frame rate

A FAST AND PRECISE ELECTRONIC SOLUTION

Standard mounting made easy

STAR5 offers a complete electronic workflow, with total control of the cameras and mandrel positioning, thanks to the high precision encoders on all the axis.

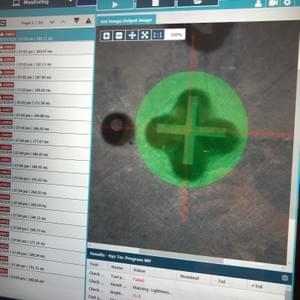

THE FIRST MOUNTER WITH A "MOUNTING ASSISTANT"

We introduce the new MOUNTING ASSISTANT software function for our mounting machines, integrated into the new "PHOTOSPLIT AI Artificial Intelligence" interface.

The operator traces the area around the register mark, and the software "locks" and "tracks" the mark, verifying the alignment between the left and right sides. A digital technology, smart, precise to the micron, as standard on our machines SYSTEC: innovative imprinting.

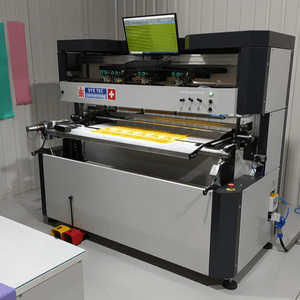

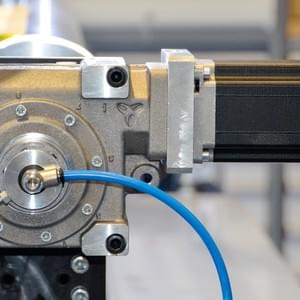

STAR 7

The semi-automatic plate mounterAUTOMATIC STICKING OF THE PLATE AND "MOUNTING ASSISTANT": WELCOME TO THE A.I. ERA

CONFIGURATION

- Cantilever opening of the air mandrel, for an easy sleeves change-over

- 2 hi.res. HD digital cameras USB 3.0 digital cameras, with faster live frame rate

- Touch-screen monitor

- Motorized cameras, with stepper motors and TOUCHLESS SLIDING system (patent pending): it is possible to move the cameras simply by putting a hand in front of them: the camera will follow it.

- Encoder for controlling the position of the cameras

- Motorized mandrel rotation, with the pedal command, with top-quality gearbox, perfect for STAGGERED MOUNTING

- Absolute rotative encoder for controlling the angle of the mandrel

- Pressure roller with "notched-engraved surface"

- Double mounting table

- Sensor for automatic positioning of the mandrel in the height, according to the sleeve repeat

- The new PHOTOSPLIT SOFTWARE for Windows 10, with the amazing function "MOUNTING ASSISTANT"

- Automatic sticking cycle of the plate

A SEMI-AUTOMATIC SOLUTION, IN THE BETWEEN OF THE STANDARD MOUNTER AND THE AUTOMATIC PLATE MOUNTERS

Are you sure that you do you really need an automatic plate mounter?

Most of the flexo companies are not really in need of an automatic plate mounter: a small-sized company with skilled operators will not catch all the benefits of an automatic mounter.

With the new STAR 7, we have created a new class of plate mounter "semi-automatic": all the advantages of the digital recognition of the marks and the automatic sticking cycle (the operator just confirms the correct alignment, and then the machine automatically sticks the plate, rotating the sleeve with a programmable controlled rotation), with a great saving of the money required for the automatic mounting device.

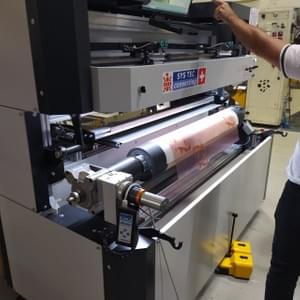

Another genial idea by SYSTEC.STAR 9

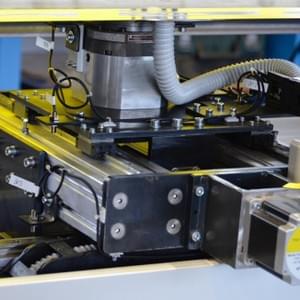

The automatic plate mounterWELCOME TO THE 4.0 DIGITAL FLEXO MOUNTER

DIGITAL CONTROL FOR PRECISE AND REPEATABLE MOUNTINGS

CONFIGURATION

- Cantilever opening of the air mandrel, for an easy sleeves change-over

- 2 hi.res. HD digital cameras USB 3.0 digital cameras, with faster live frame rate

- Touch-screen monitor

- Motorized cameras, with stepper motors and TOUCHLESS SLIDING system (patent pending): it is possible to move the cameras simply by putting a hand in front of them: the camera will follow it.

- Encoder for controlling the position of the cameras

- Motorized mandrel rotation, with the pedal command, with top-quality gearbox, perfect for STAGGERED MOUNTING

- Absolute rotative encoder for controlling the angle of the mandrel

- Pressure roller with "notched engraved surface"

- Double mounting table

- Sensor for automatic positioning of the mandrel in the height, according to the sleeve repeat

- The new PHOTOSPLIT SOFTWARE for Windows 10, with the amazing function "MOUNTING ASSISTANT"

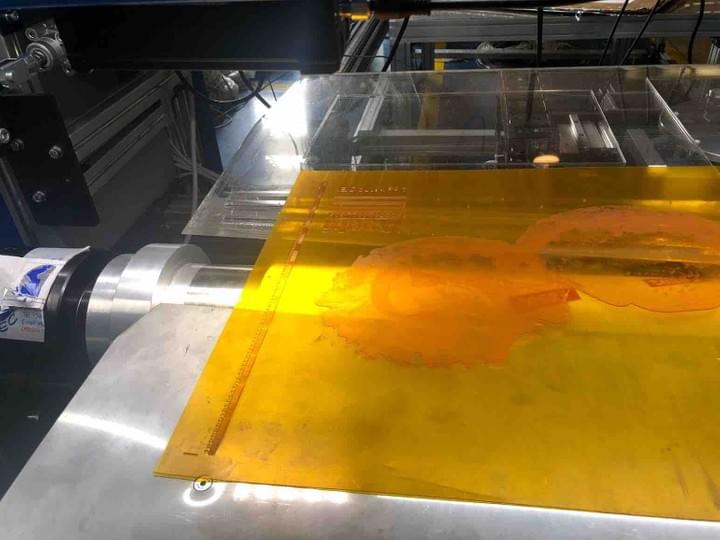

- i-TABLE automatic mounting system

- Automatic sticking cycle of the plate

THE AUTOMATIC MOUNTER WITH THE i-TABLE SMART MOUNTING SYSTEM

i-Table is the new automatic mounting system available for SYS TEC plate mounting machines.

It arose by SYS TEC research & development and permits the automatic positioning of the plates in the right mounting position.

iTable is an intelligent robotized table, it can move with 3 freedom degrees positioning the plates with centesimal precision.

It works in combination with advanced digital cameras, recognizing the cross-marks on the plates and automatically comparing them with the reference Virtual Image, and then adjusting the plate position on the sleeve.

The system provides the automatic positioning of the plates on the sleeve and the sticking of the plates on the tape with the automatic pressing roll.

HOW DOES IT WORK?

The operator simply places the plate on the table, then the machine provides the following steps:

- Automatic recognition of the marks on the plate and comparing with the Virtual Image

- Automatic adjustment of the plate to the target position

- Automatic fixing of the plates on the sticky-back with the pressing roll

THE AUTOMATIC MOUNTER WITH THE iTABLE SMART MOUNTING SYSTEM

ADVANTAGES:

- It works with any kind of cross-marks or pattern on plates

- High mounting precision

- Reduction of the time needed to mount the plates

- Elimination of the human error while mounting the plates

- Jobs repeatability

- The most advanced technology available on the market.

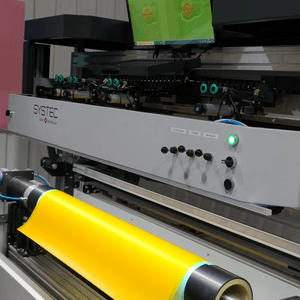

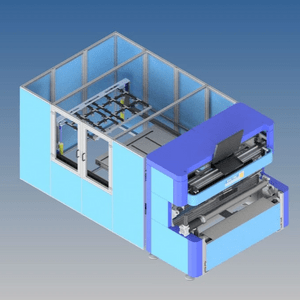

STAR X

The full automatic plate mounterTHE FIRST STEP TO A FULLY INTEGRATED FLEXO FACTORY

CONFIGURATION

- Cantilever opening of the air mandrel, for an easy sleeves change-over

- 2 hi.res. HD digital cameras USB 3.0 digital cameras, with faster live frame rate

- Touch-screen monitor

- Motorized cameras, with stepper motors and TOUCHLESS SLIDING system (patent pending): it is possible to move the cameras simply by putting a hand in front of them: the camera will follow it.

- Encoder for controlling the position of the cameras

- Motorized mandrel rotation, with the pedal command, with top-quality gearbox, perfect for STAGGERED MOUNTING

- Absolute rotative encoder for controlling the angle of the mandrel

- Pressure roller with "notched engraved surface"

- Double mounting table

- Sensor for automatic positioning of the mandrel in the height, according to the sleeve repeat

- The new PHOTOSPLIT SOFTWARE for Windows 10, with the amazing function "MOUNTING ASSISTANT"

- i-TABLE automatic mounting system

- Automatic sticking cycle of the plate

- Automatic loading of the plate on a loading deck by means of a gantry pick&place ROBOT for automatic loading

- FULL-AUTOMATIC CYCLE: automatic loading of the plate, automatic search of the marks, automatic alignment and automatic sticking on the sleeve

PLATE MOUNTING HAS NEVER BEEN SO EASY

Discover T.H.E. MOUNTER

(T.H.E. = Total Human Exclusion)

Proud to introduce the real 4.0 mounter

Discover the new full automatic mounter from SysTec

In recent years some attempts to introduce a "fully automatic mounter" have been made, with some conflicting results: the technology is too expensive, the workflow is very complicated and rigid, the processes are delicate and vulnerable. In summary, while impressive in theory the technology does not really perform to the desire or expectations of the user.

We are glad to introduce the first real 4.0 plate mounter, based on SysTec's "Virtual Image" technology and experience.

The operative workflow of our machine is so easy with precision that the operation only requires the user to load the stack of plates on the loader... and that's it!

Focus on technology

Technological heart, human flexibility

- Robotic pick & place system

- Latest generation smart cameras, have the ability to recognize any kind of reference or registration target on the plates: any pattern can become reference for the following plate, with the "Virtual Image" technology

- Siemens electronics, for the fastest and most precise and reliable operation

How does it work?

This is why we named this machine "Total Human Exclusion"

The operator places the stack of plates on the loading deck, inserts the sleeves on the mandrel, and that's all! The machine automatically provides the following steps:

- Automatic loading of the plate from the deck

- Automatic discharge of the separating sheets

- Automatic positioning of the plate on the sleeve

- Automatic research/recognition of the marks on the plate

- Automatic adjustment of the plate to the target position

- Automatic fixing of the plates on the sticky-back with the pressing roll

Advantages

Just some ideas

- It works with any kind of cross-marks, targets or patterns on new and old plates

- High mounting precision +/- 0.005 mm (0.00019”)

- Reduction of the time needed to mount the plates

- Elimination of the human error while mounting the plates

- NO conveyor belt for loading the plates, so the operator is not busy in loading them into the machine

- Jobs repeatability

- The most 4.0 advanced technology available on the market

- It works 24/7

- The fastest ROI for this kind of machine

INNOVATION IN OUR PLATE MOUNTERS

WE've revolutioned the plate mounting process

Innovation in our DNA

With our plate mounters we revolutioned the flexo mounting !

- First to introduce the VIRTUAL IMAGE to the market

- First to introduce an easy and flexible HMI interface based on Windows

- First to develope a Mounter + Demounter integrated machine

- First to apply linear servo-motors on cameras

Contact Us

SYSTEC CONVERTING

Powered by

W-TEC Srl

Via Unione 2

22075 Lurate Caccivio (CO)

P.IVA / VAT IT04123480131